Advantages and Disadvantages of 3D Printers: A Beginner’s Guide

Published: 29 May 2025

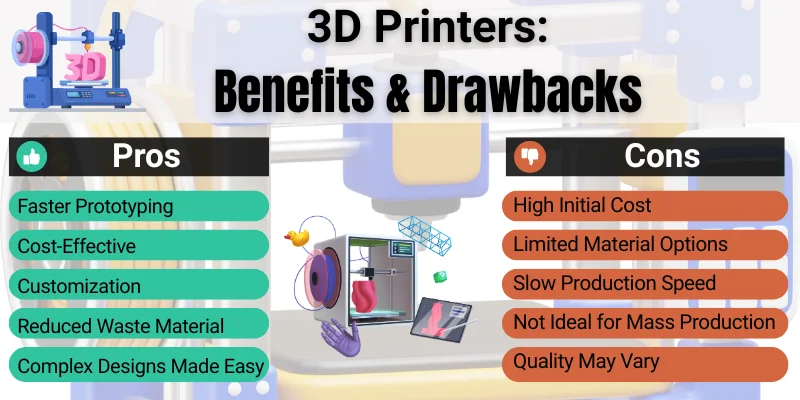

A 3D printer is a machine that creates objects layer by layer using plastic or other materials. It’s changing how we design, build, and create—right from home or small offices. In this post, I’ll walk you through the advantages and disadvantages of 3D printers in a simple way. Let’s explore both the benefits and drawbacks of this innovative technology.

Advantages of 3D Printers

3D printers offer many exciting benefits, especially for creators, designers, and businesses. They help turn ideas into real products faster, cheaper, and with less waste.

Here is quick list of top advantages of 3D printing.

- Faster Prototyping

- Cost-Effective Manufacturing

- Customization and Personalization

- Reduced Waste Material

- Complex Designs Made Easy

- On-Demand Production

- Less Inventory Needed

- Supports Innovation and Creativity

- Simplified Supply Chain

- Environmentally Friendly Options

Let’s explore above-mentioned benefits of 3D Printers in details:

1. Faster Prototyping

3D printers enable you to turn design ideas into real models quickly. You don’t have to wait for days or weeks to see the results. This is great for testing new products or improving them before final production.

- For example, a toy company can print a sample toy overnight and make changes the next day.

2. Cost-Effective Manufacturing

One significant benefit of 3D printers is the cost savings they offer. You don’t need expensive molds or tools to make each item. This is ideal for small production runs or one-time creations.

- A startup can print parts without incurring significant costs on factory setup.

3. Customization and Personalization

3D printing makes it easy to create unique, custom items. You can customize the shape, size, or design to suit each person’s needs. This is useful for items such as dental tools, hearing aids, or custom-made gifts.

- For example, a designer can print a bracelet with a customer’s name on it.

4. Reduced Waste Material

Traditional manufacturing involves cutting material from large blocks, which generates waste. But 3D printing adds only what’s needed, layer by layer. This reduces leftover materials and helps save costs.

- It’s a cleaner way to manufacture parts, such as phone cases or machine tools.

5. Complex Designs Made Easy

Some shapes are too difficult or too costly to produce with conventional machines. 3D printers can easily handle these complex designs. Engineers and artists use this to create detailed models or tools.

- For example, a student can print a working model of a human heart for science class.

6. On-Demand Production

With 3D printing, you don’t need to make everything in advance. You can print items only when needed. This saves storage space and avoids extra costs.

- A business can quickly print spare parts only when a customer asks.

7. Less Inventory Needed

Instead of storing hundreds of parts, companies can print them as needed, according to orders. This reduces the need for big warehouses. It also helps prevent waste from unsold items.

- Small shops can benefit by offering made-to-order products.

8. Supports Innovation and Creativity

3D printers make it easier to turn ideas into real products. Students, inventors, and creators can try new things without incurring significant costs. It’s fun and educational too.

- A child can design and print their toy using simple software.

9. Simplified Supply Chain

With 3D printing, you don’t need many parts from different suppliers. You can make most things in one place. This makes the process faster and easier to manage.

- A local business can produce everything in-house, saving time and effort.

10. Environmentally Friendly Options

Some 3D printers use biodegradable or recycled materials. They also reduce shipping and packaging needs. This lowers the carbon footprint and helps the planet.

- For example, a fashion brand can print shoes from eco-friendly filaments.

Read Also : Top 15+ Essential Functions of a Printer (With Features & Examples)

Disadvantages of 3D Printers

While 3D printing is useful, it also has some downsides. Like any technology, it has its limits and challenges. Here is quick list of common disadvantages of 3D printers:

- High Initial Cost

- Limited Material Options

- Slow Production Speed

- Not Ideal for Mass Production

- Quality May Vary

- Requires Technical Knowledge

- Potential for Misuse

- Post-Processing Often Needed

- Energy Consumption Can Be High

- Size Limitations for Large Objects

Let’s explore the above-mentioned drawbacks of 3D printers that you should be aware of.

1. High Initial Cost

3D printers can be costly to buy, especially high-quality ones. Some machines cost hundreds or even thousands of dollars. This makes them more difficult for students, beginners, or small businesses to afford.

- You also need to buy materials and parts, which adds to the cost.

2. Limited Material Options

Most 3D printers are limited to working with plastic, resin, or nylon. Printing with metal, food, or glass requires expensive, specialized machines. This limits what you can make at home or in small setups.

- Some useful materials may also not be available in every region.

3. Slow Production Speed

3D printers build objects layer by layer, which takes time. Printing one item may take hours, depending on size and detail. It’s fine for a single piece but not practical for making hundreds.

- Businesses needing fast output may struggle with this.

4. Not Ideal for Mass Production

3D printing is most effective for small batches or custom items. It’s not designed for mass production of the same item quickly. Traditional factories still excel in terms of speed and cost for mass production. So, big companies may still prefer old methods.

5. Quality May Vary

Not all 3D prints come out smooth and perfect. Some may have rough edges, lines, or weak spots. The final quality depends on the printer, the settings, and the user’s skills.

- Beginners may face issues with consistency.

6. Requires Technical Knowledge

You need to learn how to use 3D design software and printer settings. It takes time to understand file formats, slicing, and maintenance. Beginners may feel confused at first and need guidance.

- Troubleshooting can also be tricky without support.

7. Potential for Misuse

Sadly, 3D printers can be used to make harmful or illegal items. This includes counterfeit products, weapons, or unauthorized medical devices. This risk necessitates the implementation of proper rules and effective monitoring.

- Responsible use is very important with such powerful technology.

8. Post-Processing Often Needed

After printing, many items require additional work, such as sanding, washing, or curing. This is known as post-processing, which adds time and effort. It may also need extra tools or chemicals. So, the process doesn’t always end when the print is done.

9. Energy Consumption Can Be High

Some 3D printers consume a significant amount of electricity, particularly during extended print sessions. This increases your electric bill and isn’t great for the environment. Large industrial machines often consume more power than home devices.

- Choosing energy-efficient models is a smart move.

10. Size Limitations for Large Objects

Most home and small office 3D printers are limited to printing small items. If you want to produce large parts, you need a larger and more expensive machine. This limits what you can build unless you split it into smaller parts.

- For example, printing a full-size chair isn’t possible with most basic printers.

Conclusion

So, guys, I will wrap up now. We saw the main advantages and disadvantages of 3D printers. They can help create amazing things quickly and cheaply. However, they also have limitations, such as cost and speed. My advice? Try 3D printing with an open mind. It can be both fun and useful, especially if you enjoy creating things.

If you found this helpful, share it with your friends! If you have any questions, please feel free to leave a comment below. Want more beginner-friendly tech guides? Stay tuned!

FAQs: Beginners Ask About 3D Printers

Here are some common questions beginners ask about 3D printing.

A 3D printer is a machine that makes real objects from digital designs. It builds items layer by layer. You can create a wide range of toys, tools, and other items with it.

It reads a 3D design file on the computer. Then, it adds material layer by layer to form the object. The process is like stacking thin sheets until the item is complete.

Most 3D printers use plastic or resin as their material. Some special printers can use metal or even food ingredients. The material depends on the printer type and the item you want to create.

Basic 3D printers can be affordable for hobbyists. But high-quality machines cost more. It’s a good idea to start with a simple printer if you’re new.

You can print many things, but not everything. Some objects need special materials or big printers. Also, some designs need post-processing after printing.

Printing time varies depending on the size and level of detail. Small items can take minutes. Larger or more complex designs might take hours or even days.

You should learn basic software to prepare designs. Some printers are easy for beginners. However, it’s helpful to watch tutorials or ask for help initially.

No, 3D printing is best for small batches or prototypes. Factories typically employ faster methods for large-scale production. It’s great for custom or unique items.

Prints can have rough surfaces or errors if settings are wrong. Some materials may clog the printer. Learning the machine well helps avoid these issues.

Some 3D printers use plastic, which can create waste. But they often use less material than traditional methods. Eco-friendly filaments and recycling can reduce impact.

Top 5 pros: fast prototyping, low cost for small jobs, custom designs, less waste, and creative use.

Top 5 cons: high starting cost, limited materials, slow speed, not for big batches, and sometimes rough quality.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks